A Broken Glass. A Whole New Future.

It starts with something simple: you drop a glass. It shatters. In most homes, that’s the end of the story — sweep, trash, forget.

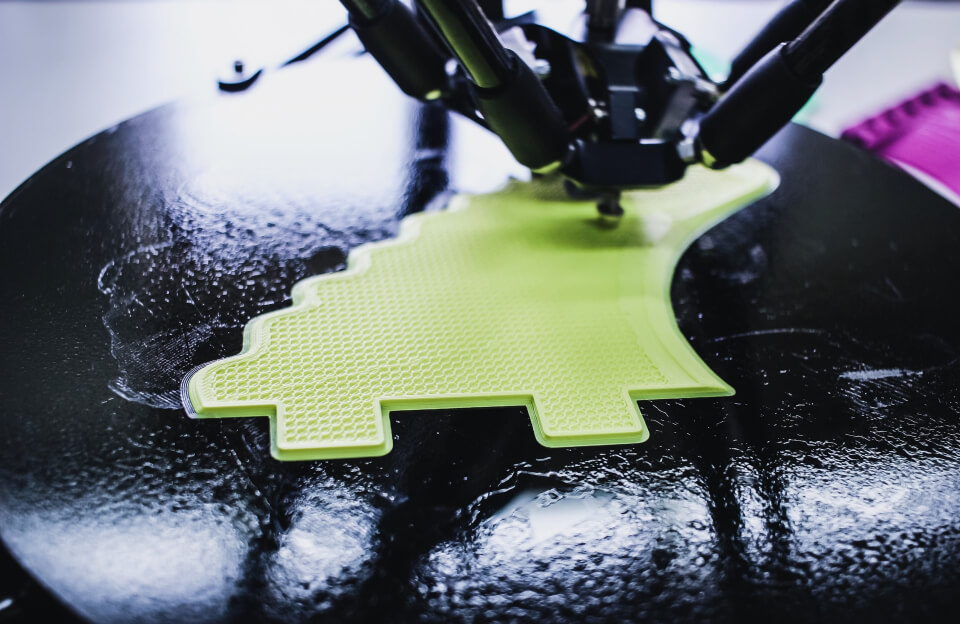

But what if, instead of tossing it, you could open your phone, scan the pieces, and 3D-print an identical replacement in your kitchen?

This is not science fiction. It’s the emerging reality of additive manufacturing, and it’s poised to transform how we think about objects, ownership, and sustainability.

The Rise of Consumer-Grade 3D Printing

Until recently, 3D printing was confined to labs, industrial facilities, and maker communities. But in 2025, the technology is finally reaching a consumer tipping point:

- Glass printing breakthroughs now allow for more complex shapes and transparent materials.

- Affordable desktop printers support not only plastics and resins, but also ceramics and glass-like composites.

- AI-generated design files can recreate common household items in seconds.

This convergence means we may soon treat 3D printing the way we treat microwaves or dishwashers — just another household utility.

🧠 Think about it: Instead of reordering fragile goods, we’ll reprint them.

Why It Matters for CEOs and Innovators

The implications go far beyond kitchenware. For business leaders, 3D printing represents a new industrial mindset:

1. Hyper-Personalized Manufacturing

Products made on demand, to exact specifications, from wherever the customer is.

2. Localized Supply Chains

Print it where it’s needed, cutting shipping costs, emissions, and delays.

3. Circular Economy by Design

Broken parts become source material. Waste becomes value. The loop closes.

4. Disruption of Traditional Retail

In the future, a brand may sell not a product — but the blueprint to print it.

“The next industrial revolution won’t be about mass production. It will be about mass personalization.” — Trend analyst, 2025

Glass Printing: A Milestone in Materials Science

Printing with glass has long been a challenge due to its high melting point and delicate structure. But recent research at institutions like MIT and ETH Zurich has opened new frontiers:

- High-temperature 3D printing systems now allow molten glass to be layered with precision.

- Digital Glass Design tools enable real-time modeling of complex optics, structures, and textures.

- Recycled glass filament creates a sustainable, closed-loop ecosystem.

We’re now imagining homes where a broken wine glass, a cracked lamp shade, or a chipped smartphone screen could be repaired — or reinvented — at home.

The Consumer Future: Apps, Scans, and Smart Printers

Imagine this scenario:

- Your child drops a favorite mug.

- You open an app, scan the broken item.

- AI reconstructs the missing details.

- Your countertop 3D printer reproduces a perfect match in an hour.

It’s convenience. It’s sustainability. It’s personalization — all rolled into one seamless user experience.

This is the next UX frontier for product design.

Challenges Ahead: Safety, IP, and Scalability

Of course, democratized 3D printing also brings risks:

- Safety standards must evolve for home-printed tools, containers, or medical parts.

- Intellectual property laws must address the sharing of design files and replicas.

- Material sourcing and recycling infrastructure must scale with adoption.

Companies who solve these problems early will become the platform players of a whole new economy.

Final Thoughts: From Broken to Better

A broken glass may soon become more than an inconvenience — it could be an opportunity.

An opportunity to rethink manufacturing, empower consumers, and reduce waste. An opportunity to go from passive buyers to creative makers.

In the near future, we won’t ask “Where can I buy this?”

We’ll ask: “Can I print this?”